Mhs - Material Handling Supply Inc. for Dummies

Mhs - Material Handling Supply Inc. for Dummies

Blog Article

Mhs - Material Handling Supply Inc. Fundamentals Explained

Table of ContentsThe 10-Second Trick For Mhs - Material Handling Supply Inc.How Mhs - Material Handling Supply Inc. can Save You Time, Stress, and Money.Getting The Mhs - Material Handling Supply Inc. To WorkThe Of Mhs - Material Handling Supply Inc.The Facts About Mhs - Material Handling Supply Inc. UncoveredThe Greatest Guide To Mhs - Material Handling Supply Inc.

This line is called the line of activity. forklift rental watkinsville, ga. If the bottom of this line goes beyond the stability triangle due to the fact that a load is also heavy or also high, or due to the fact that the forklift is not on a degree surface area it will tip over. An upright line extending from the center of mass of the vehicle-load mix must remain inside the security triangle to avoid the forklift from tippingThe other concept to understand is the forklifts center of gravity. When unloaded, the forklifts center of gravity is ideal about below.

Larger lots change the center of gravity ahead also further. Raising the tons additionally shifts the facility of gravity onward. In order to prevent the lift from tipping, the consolidated center of mass of the load and the lift need to remain inside the stability triangular (at ground level) in any way times.

3 Easy Facts About Mhs - Material Handling Supply Inc. Described

If you have a well balanced lots, the load is unlikely to affect the side-to-side center of gravity. https://www.gaiaonline.com/profiles/mhsinc30677/46666971/. Yet if you drive on a sloped surface, your center of mass can pass beyond the security triangular and the lift can tip. Every forklift has an identification plate that details important information regarding the truck

To make sure that the center of mass of your forklift remains inside the security triangle, don't try to lift anything larger than the identification plate permits. Regardless of how busy you are, you should examine your forklift prior to using it. If you do discover something that can impact the safety of the vehicle you should report it immediately.

Follow the drivers manuals provided by the tools supplier. These guidebooks explain the secure operation and maintenance of forklifts. Remember, the operator is responsible for the safe operation of the forklift. Do a pre-operation assessment before every change. If the forklift is made use of all the time, evaluate it either prior to each change or after each change.

Indicators on Mhs - Material Handling Supply Inc. You Need To Know

It is finished in 2 parts: the walk-around assessment, and, the seated evaluation. OSHA does not call for documentation of an everyday examination. However it's a good concept to have a list to make certain you don't miss out on any steps. These checklists can also be conserved as a component of the upkeep record.

Inspect the condition of the tires. If the forklift is an outside forklift with pneumatic tires, check the air pressure and try to find too much endure the tires. A tire with low atmospheric pressure could create the Visit Website lift to tip when a tons is elevated. Could a tire failing.

What Does Mhs - Material Handling Supply Inc. Do?

Try to find fractures or various other signs of wear. Check all liquid levels. Check the engine for any indicators of wear, loosened connections, or leaks. Wipe up any type of excessive oil or various other flammable compound. Try to find fractures or deformities in the forks, back-rest, pole, and above guard. Check the recognition plate to make certain it is undamaged and legible.

Start the engine. Always begin the engine while seated in the operator's positionnever while standing along with the forklift. Check all assesses and advising lights, and the battery or fuel degree. Obtain accustomed to the controls. Lift and lower the forks, and turn the mast. Make certain that whatever works smoothly and is plainly identified.

Mhs - Material Handling Supply Inc. Things To Know Before You Get This

You'll require to sound the horn at crossways, and wherever vision is obstructed. Inspect the brakes by depressing the brake pedal. There must be some resistance. Set and evaluate the parking brake. Examine the guiding. A great deal of play or hard guiding will certainly lower your control. Move the forklift ahead a few feet.

Look for stimulates or fires coming out of the exhaust system. If you find anything wrong with the forklift during the walk-around or seated evaluation, do not operate it up until it has actually been fixed.

Not known Incorrect Statements About Mhs - Material Handling Supply Inc.

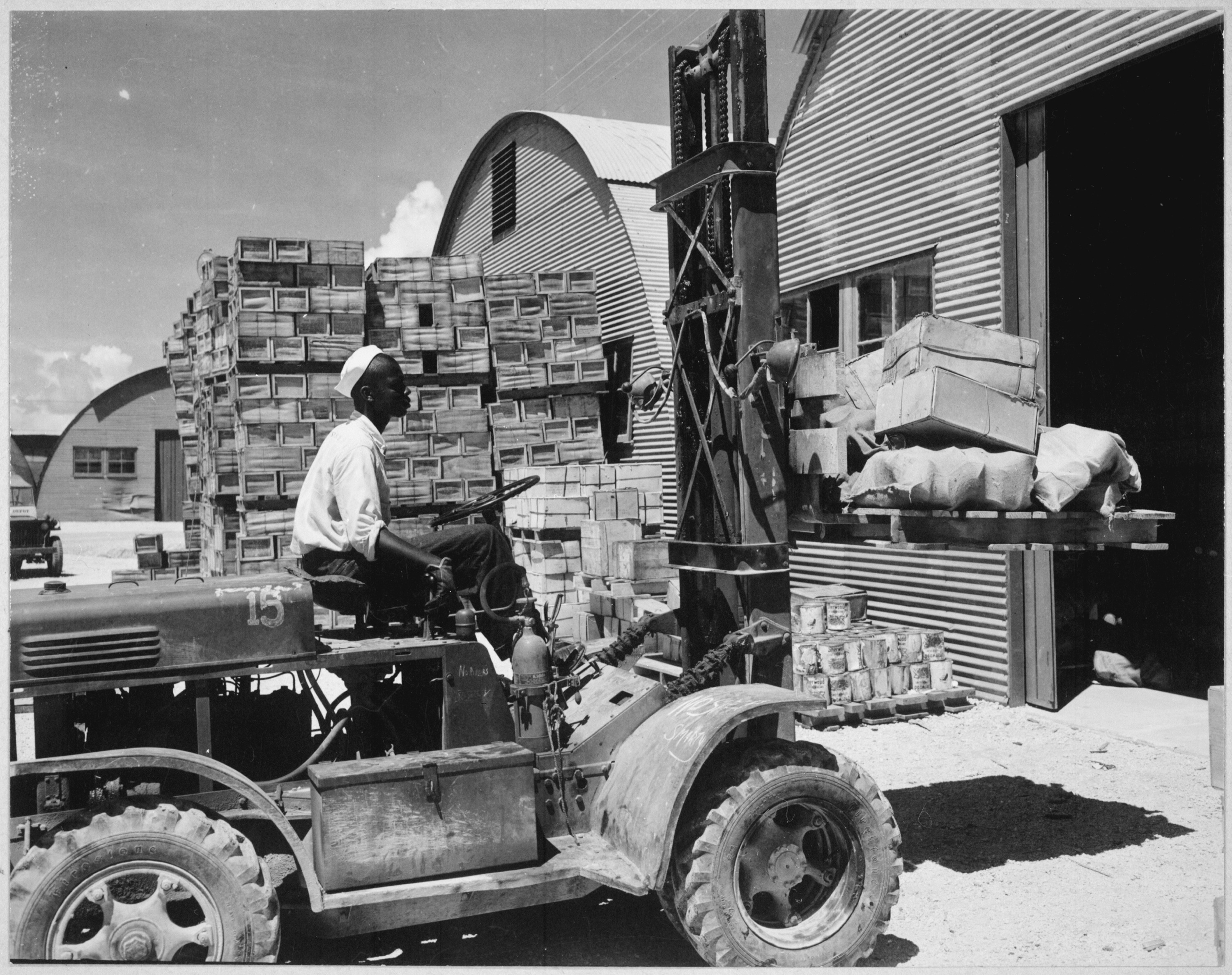

Forklifts have many moving parts and pieces that enable the forklift to operate properly. Understanding the terms of the components and composition of a forklift is very important for reliable communication with others while on the job - https://www.figma.com/file/FCBd6aHTDRFLA85FpKRsIO/Untitled?type=design&node-id=0%3A1&mode=design&t=IJckpFk7ys2cuE5q-1. Right here are several of the fundamental attributes and components that make up the anatomy of a forklift truck

For a lot of forklifts, the mast is developed toward the front of a forklift and directly in the forklift operator's line of vision. Forklift poles come with different sections that elevate or reduced the forklift carriage along with the forks.

Report this page